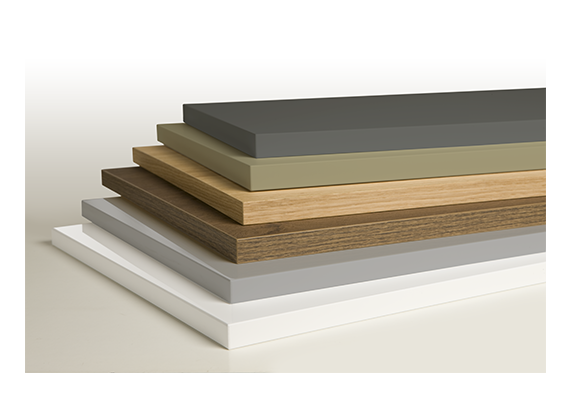

IXTEX WOOD is an unprecedented, transparent, matt finish for wood. It’s achieved by applying the IXTEX MATT finish to wooden surfaces. It pairs the appeal and the pleasant feel of the 3 gloss matt finish with a natural look while offering a degree of abrasion and scratch resistance that has never before been achieved by a finish applied to wood.

The IXTEX WOOD finish, on an MDF, chipboard or twin board core, is available in any shade required and – if necessary – can be delivered JIT.

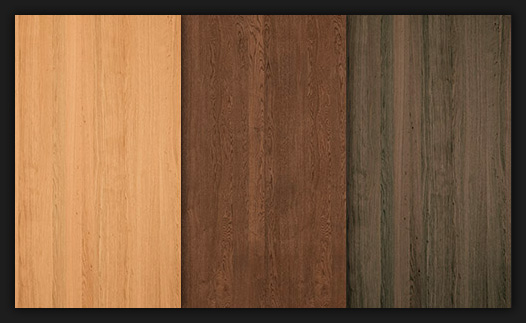

Natural

Natural

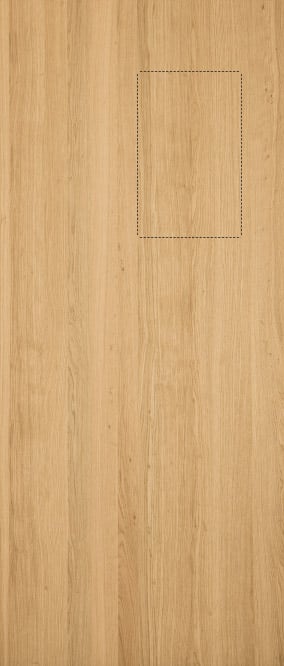

Contemporary Oak

SINGLE PANEL 2800×1220 mm

DOOR – Natural Contemporary Oak

DOOR – Terra Contemporary Oak

DOOR – Muschio Contemporary Oak

JUST IN TIME

JUST IN TIME

Available in a variety of wood types and colours. MOQ 100 panels.

MDF

MDF Chipboard

Chipboard Twin

Twin

EDGING

EDGING MATERIALS

AVAILABLE IN THE SAME COLOURS AS THE PANELS.

On request, TPS can also supply different edging materials for doors made from IXTEX MATT, IXTEX WOOD and ILUX panels.

WHY YOU SHOULD CHOOSE

Anti-bacterial properties

The ASA (Antibacterial Silver Action) treatment applied on request reduces the growth of surface bacteria in 24 hours by 99% thanks to a silver ion-based additive used in the coating cycle. Moreover, ASA guarantees that this anti-bacterial action lasts over time while leaving the characteristics of the finishes unchanged, including their high chemical and mechanical resistance.

Anti-fingerprint finish

Our surfaces are anti-fingerprint which means you can touch them without leaving a mark.

Abrasion and scratch resistance

The high abrasion resistance of our panels is tested by subjecting their surfaces to a cycle of 160 rubs using abrasive nylon/alumina material. Grade 5 scratch resistance – corresponding to a Newton force of 9 – is the highest that can be obtained and is proven by tests in compliance with the EN-15186 European standards that define a resistance to scratches deep enough to be easily seen on a vertical surface.

Repairability

Any small scratches produced on the surface of our panels can be repaired using a quick and easy thermal process.

Tests performed by cutting-edge systems

The compliance of our products with high quality standards is proven by strict tests and quality controls performed using some of the most accurate optical and electronic systems in the world. Any panels with surface defects are automatically identified and immediately discarded.

High chemical resistance

Our surfaces are tested using strict processes to offer high resistance to class 1B chemical agents, according to the definition of the German

CEE DIN-68861-1:81 standard.

FSC® (C143521), TÜV and CARB certifications or PEFC (PEFC/18-31-1055)

The initial semi-finished MDF panels come with the FSC certification or, on request, with the PEFC certification, both of which testify that they are made using wood from responsibly-managed forests or plantations. They are also CARB (California Air Resource Board) certified, based on the ATCM (Airborne Toxic Control Measure) regulation aimed at reducing and monitoring the formaldehyde emissions of wood-based materials used in California.

Very low VOC emissions

Our panels feature extremely low emissions of VOC (Volatile Organic Compounds), i.e. much lower than the minimum quantities normally requested by the furniture industry. VOC are hydrocarbons that – at normal room temperature – are present in a gaseous state. They can have an organic or anthropogenic origin.

Melamine or wood in the same colour/finish on both sides of the panel

The front side of our IXTEX MATT, IXTEX WOOD and ILUX panels is covered by a protective film. The reverse side is in the same colour and finish.

CONTACT US

FOR MORE INFO